When people are challenged or tested, we sometimes say, “Let’s see what they’re made of.” It’s an expression that comes from craft and manufacturing. People are all made of the same stuff of course, but we associate quality and strength with materials. We even name entire periods of human history after the materials that were in common use—the Bronze Age and the Iron Age for example. We’ve written a lot about the premium top-grain leather we use in our wallets and clutches. The other primary material in many of our products is metal—steel, aluminum, brass, or titanium. Today, we’re going to look at each of these metals in more detail.

Steel

One of the most commonly used materials in manufacturing and construction is steel. This is due to its high fracture resistance and tensile strength. In other words, steel can take a lot of punishment without chipping or snapping. Although it is commonly associated with the industrial revolution, steel had actually been around for thousands of years before efficient mass production techniques were developed. A well known example of pre-industrial steel is the legendary Damascus steel. It can be recognized by the swirling wave-like pattern on its surface. It was said to be of unparalleled strength and sharpness. Many manufacturers make Damascus steel today, but the traditional techniques used to forge it in the ancient past have been lost to time.

One of the biggest breakthroughs in steel production was the invention of stainless steel, which we use in our wallet frames. The addition of chromium and other elements to the alloy makes stainless steel rust resistant. The steel we use to make our Trek Knife and Talon Carabiner—CPM S35VN—is a premium variety of stainless steel. Its hardness and edge retention make it ideal for wear resistant knives and other tools that benefit from these properties.

Aluminum

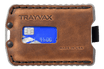

The first thing that comes to mind when people think about aluminum is often flimsy pop cans. Aluminum is everywhere now, but it was very hard to obtain for most of human history. There was even a time when aluminum was more precious than gold. A little over a century ago, new methods were developed to separate aluminum from other minerals, and it suddenly went from rare to abundant over the course of a few decades. Aluminum is hard yet very lightweight. This makes it suited for many applications, from kitchen foil, to aircraft, to the front plate of our Original 2.0 Wallet and the buckle on our Cinch Belt. Just like steel, there are many varieties of aluminum alloy. Aircraft grade aluminum simply means it is fit for use in aircraft. The varieties we use are 6061 (front plates, grips) and 7075 (belt buckles). Both of these are considered aircraft grade. 7075 is one of the strongest grades of aluminum—rivaling the strength of many steel alloys. After all, you wouldn’t want to make an airplane or a wallet out of old pop cans.

Brass

This is the only alloy on our list to have a section of an orchestra named after it. In addition to its use in musical instruments like trumpets and trombones, brass is commonly found in the handles and fixtures of buildings and furniture. Aside from its appearance, brass is a popular material due to its low melting point, workability, and electrical conductivity. Brass is a copper alloy, and as such, it is prone to oxidation. This means it will develop a patina over time, typically becoming darker and less reflective. This patina can be removed by cleaning or prevented with sealants, but many people prize patinated brass items for their uniqueness and authenticity. A patina also protects the brass from corrosion. In addition to the brass version of our Contour Wallet, we also make brass carabiners.

Titanium

When a material is named after the Titans of Greek mythology, you know you’re dealing with something special. The element titanium (Ti) was first discovered in the 1790s, but it would take more than a century for scientists to be able to extract pure metallic titanium from ores. This was in 1910, and titanium metal would not be used outside of a laboratory setting until 1932. Titanium has the highest strength-to-density ratio of any metallic element, so the development of titanium alloys was a breakthrough for many applications. This strong yet light material has been used in everything from spacecraft to prosthetic implants. Everyday carry items such as our Titanium Contour Wallet and our Titanium Carabiner benefit from titanium’s lightweight strength as well as its resistance to dents and corrosion. Titanium gear will look great and perform reliably for many years.

Every material we use has a purpose and a history. Looking back at the breakthroughs that brought these materials to us is humbling and inspiring. As a modern American manufacturer, we are committed to the continuous improvement of our products by experimenting with new combinations of materials and methods. What materials would you like to see us use more in the future?

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.